Industrial particulate matter

What is particulate matter?

Why is particulate matter dangerous?

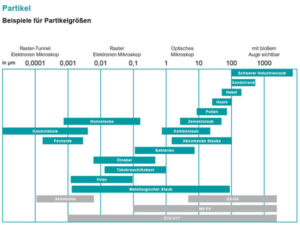

The particles in particulate matter are very small and carcinogenic. The smaller the particles, the deeper they can penetrate the lungs when inhaled and remain there. When measuring particle sizes, the focus is on the respirable levels of immissions. The smaller the particles, the deeper they can get into the lungs and cause irreparable damage, which can lead to lung cancer. Suspended dust includes all airborne particles. These are subdivided into PM10, of which half of the particles have a diameter of 10 μm. The other half consists of PM2.5 with a particle diameter of 2.5 mm and smaller. For example, modern laser processes emit particles in the range of nanometers, which is only one millionth of a millimeter. The concentration of the smallest particles is increasing steadily nowadays, while the number of greater particles is decreasing. This results to a rising danger to humans.The simulation of the internal airways allows the measurement of the particle concentration in the deposition process. Particles with an aerodynamic diameter of 10 micrometer are fully sucked into the inner airways to the bronchi. The evaluation of the larger particles is based on their percentage, which decreases with advancing size and reaches 0% at approximately 15 μm. Since 1997, the directive 2008/50/EG has been supplemented by PM2.5. It measures respirable particulate matter and defines ultrafine particles with a thermodynamic diameter of less than 0.1 mm.

In addition to the particle sizes, dusts can also be classified according to their nature, formation, physical properties, chemical compositions, shape or color. For example, other models determine the material’s structural toxicity or perpetrator. However, a full consideration is only possible with the inclusion of multiple models.

Which guidelines apply to particulate matter regarding to the used filters?

Previously, particulate matter was assessed according to the DIN EN779. However, this only referred to the particle size 0.4 µm and evaluated the efficiency of an air filter as an average over a load of synthetic laboratory dust. Due to its limited informative value, it has been replaced by the DIN EN ISO 16890. It came into force in January 2017 and has been valid since mid-2018.The ISO is also used by the WHO and divides the filters into four groups. The degree of separation determines the affiliation. A filter must deposit at least 50% of the respective particle size. For example, an ISO ePM1 filter deposits at least 50% of the PM1 particles. If a filter separates less than 50% PM10, it falls into the category coarse dust filter (= ISO coarse). The e stands for efficiency. The respective percentages indicate the percentage of the corresponding particles that the filter deposits.

What are the causes and consequences of particulate matter?

Particulate matter can cause respiratory diseases, asthma, allergies or cardiovascular diseases. Fine dusts from inorganic substances such as metal dusts are particularly critical. The body cannot break them down. Permanent exposure to high dust concentrations leads to an overload of the lungs’ cleaning mechanism in the long term. The dust particles then demonstrably stay in the lungs. As a result, chronic bronchitis can develop. 1

Only an air filter and extraction system can provide adequate protection.

1 Source: https://www.dguv.de/staub-info/erkrankungen/reinigungsmechanismus-der-lunge/index.jsp (DE)

Please call us at +49 (0) 7082/9473-0 or send us an e-mail to info@tbh.eu.