Explanation ESD

What does ESD stand for?

ESD (Electrostatic sensitive devices) is an exchange of static electricity between two bodies. The electric charge can be generated by friction between two different materials, e.g. on synthetic clothing or when moving plastic containers. ESD is caused by a lack or excess of electrons on a body’s surface. These bodies have an ESD potential on their surface and can affect neighboring and/or adjacent bodies due to the created electrostatic field, posing a significant risk in various production processes.

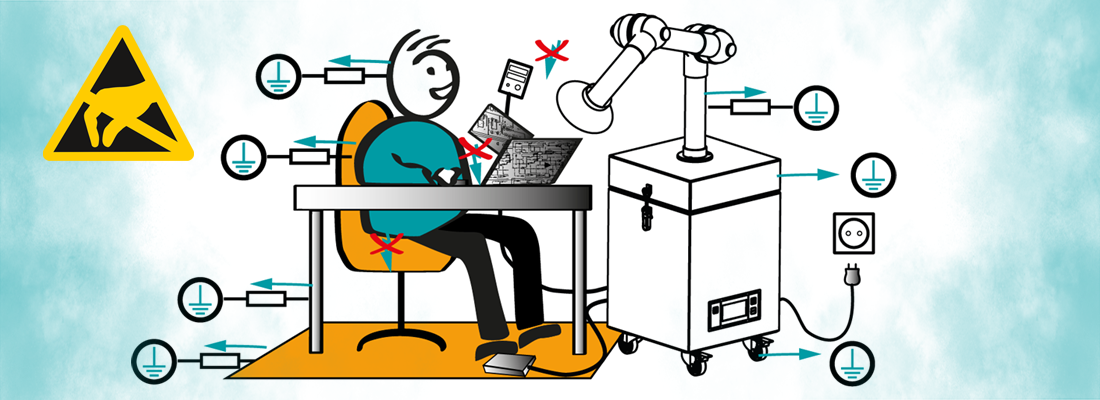

Electrostatic charging can occur in almost any body. The electronic energy that can accumulate in the human body is about 10-30 milli-joules. The strength of the electrostatic field can be up to 20 kV. With a current flow of up to 100 A/ns, short-term discharge currents of up to 30 A can be achieved. Due to the charge generated by friction, e.g. when walking on carpeted floors, contact with sensitive components can damage them. Electrostatic discharges generate voltages of several 10,000 V due to frictional electricity.So-called Electrostatic Protected Areas (EPA) can be set up at the workstations for protecting ESD-sensitive components. The workplaces have conductive and grounded table and floor coverings, so-called ground potential reference surfaces, as well as grounded tools. The workers’ clothes and shoes are made of antistatic material.

The Screen Equipment Regulation includes measurements to reduce electrostatic discharges and protect health. There are the static discharge as well as the inductively induced interference, the electromagnetic interference (EMI).

| ESD classes | Voltages that cause damages |

|

ESD class 1 |

Sensitive against ESD voltages between 0 V and 1.9 kV |

|

ESD class 2 |

Sensitive against ESD voltages between 2 kV and 3.9 kV |

|

ESD class 3 |

Sensitive against ESD voltages between 4 kV and 15.9 kV |

|

ESD class insensitive |

Sensitive against ESD voltages above 16.0 kV |

Why wearing ESD shoes?

ESD safety shoes are designed to protect against electrostatic discharge. ESD discharges in workplaces can be the cause of serious accidents (e.g. start a fire near flammable materials), as well as damage machines and their sensitive components. ESD labeled footwear differs from normal safety footwear, which only has an antistatic marking (A), i.e. it constantly discharges the static electricity accumulated by the human body to the ground. Their use is regulated in accordance with EN ISO 20345:2011. Whereas an antistatic shoe has an electrical resistance of 100 kiloohm to 100 megohm, an ESD shoe has an electrical resistance in the range of 100 kiloohm to 35 megohm.An ESD shoe is always antistatic, but an antistatic shoe does not necessarily fit into the ESD category. A yellow marking makes it immediately recognizable. The marking is separate from the CE marking, as this is a standard in the product protection industry. If the shoes or clothing meet the standard, they are marked ESD. A marking with SI indicates antistatic.

ESD in TBH filter and extraction systems

The demand from ESD environments for a discharge of electrostatic discharges is based on a high-resistance resistor according to IEC 61340-5-1 <35 megaohm, in order to keep the leakage currents low. This protects sensitive electronic components from overvoltage. The protection of humans has the highest priority. Therefore, the user must not come in contact with the extraction system.

Capture elements can be grounded using their ground connection with high resistance to the system. Thus, a touch is not a problem. The system should be placed under a worktable so as not to be in the normal working environment. During maintenance work, attention must be drawn to any critical electronic components in the environment or to remove the system from the ESD area during maintenance.

Do you have any further questions?

Please call us at +49 (0) 7082/9473-0 or send us an e-mail to info@tbh.eu.