What are particulate air filters?

Fine dust filters, also known as HEPA filters (High Efficiency Particulate Air), are highly efficient air purification systems. They play an important role in improving air quality by removing tiny particles, aerosols and toxic dusts from the air. In addition, particulate filters provide important health protection.

Classification and standards of particulate air filters

Particulate air filters are classified according to DIN EN 779 and ISO 16890, based on particle size. The following categories are distinguished:

– ISO Coarse: Retention capacity against ISO A2 dust

– ISO PM10: Particles ≤ 10 μm

– ISO PM2.5: Particles ≤ 2.5 μm

– ISO PM1: Particles ≤ 1 μm

In addition, HEPA Class H13 and H14 filters are the highest HEPA class and are used to collect industrial particulate matter.

Effective separation with particulate air filters

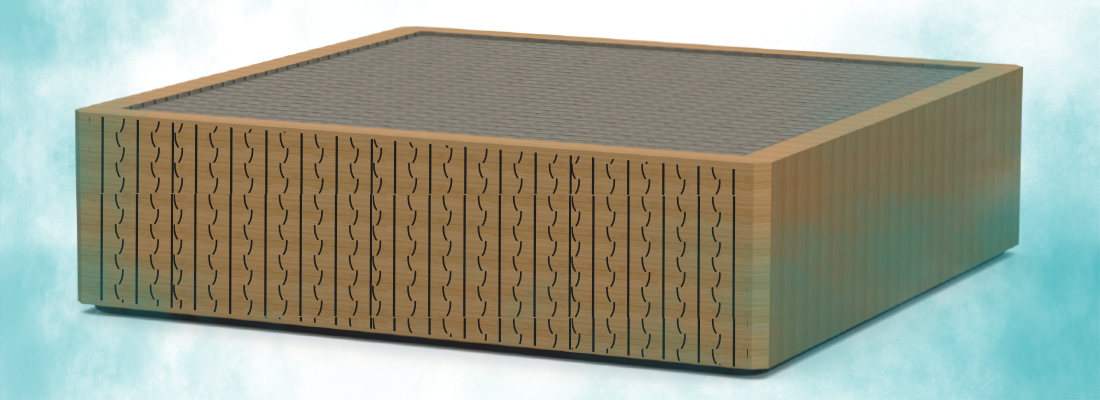

High-quality particulate filters, especially HEPA filters, consist of a complex network of fibers. They have the following characteristics:

- Over 1000 layers of cellulose and synthetic materials

- Filtration efficiency of > 99.9% for particles between 0.1 and 0.3 µm

- Fewer than 3 particles in 10,000 pass through the filter

However, regular replacement of particulate filters is essential for optimal performance and hygiene.

The EN 1822-1:2009 standard classifies particulate filters into EPA (E10-E12), HEPA (H13-H14), and ULPA (U15-U17). As a result, regular change intervals prevent the formation of germs and bacteria that can occur when high concentrations of pollutants are present in saturated filters. In the USA, on the other hand, HEPA has a fixed filtration efficiency and is comparable to filter class H13 according to EN 1822-1.

Protective measures and use of particulate air filters

In dusty environments, particulate filters are part of a comprehensive approach to protection: This includes:

- Dust avoidance at the source

- Direct extraction at the point of emission

- Use of efficient ventilation systems with fine dust filters

- Use of personal protective equipment

In addition, modern dust collection systems with particulate filters have warning systems that sound an alarm when filter performance drops, thus ensuring continuous protection of workers.

For more information on high quality particulate filters and customized dust collection solutions, please contact us or visit our product overview.

Do you have any further questions?

Please call us at +49 (0) 7082/9473-0 or send us an e-mail to info@tbh.eu.